The growing awareness of skin protection against harmful UV radiation has propelled the demand for sun-protective clothing, particularly garments with certified UPF (Ultraviolet Protection Factor) ratings. Unlike sunscreen, which requires reapplication, UPF-rated fabrics offer continuous protection by blocking both UVA and UVB rays. However, the reliability of these claims hinges on standardized testing methodologies that evaluate a fabric’s true protective capabilities. Understanding how UPF values are verified is crucial for consumers and manufacturers alike.

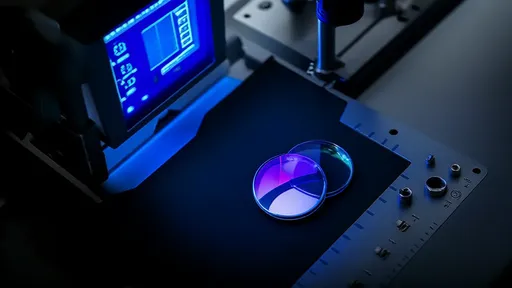

UPF testing begins with a rigorous examination of fabric composition and construction. Factors such as fiber type, weave density, color, and finishing treatments (e.g., chemical UV absorbers) significantly influence a garment’s ability to block ultraviolet radiation. For instance, tightly woven polyester or nylon fabrics often outperform loose knits, while darker colors absorb more UV light than lighter shades. Laboratories simulate real-world conditions by subjecting fabric samples to controlled UV exposure using spectrophotometers or solar simulators, measuring the amount of radiation that penetrates the material.

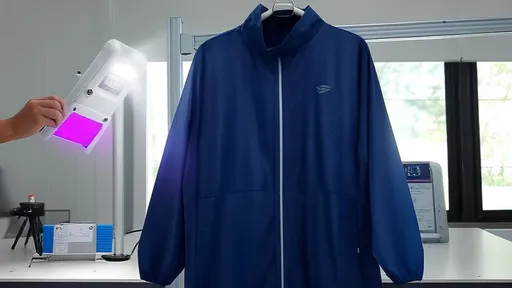

One critical aspect of UPF verification is the distinction between initial and post-treatment ratings. A fabric may boast a high UPF when new, but its effectiveness can degrade after repeated washing, stretching, or exposure to chlorine or sweat. Reputable testing protocols, such as those outlined by the Australian/New Zealand Standard (AS/NZS 4399) or the American Association of Textile Chemists and Colorists (AATCC 183), require pre-treatment simulations—like multiple wash cycles or abrasion tests—before assigning a final UPF rating. This ensures the garment maintains its protective qualities over time.

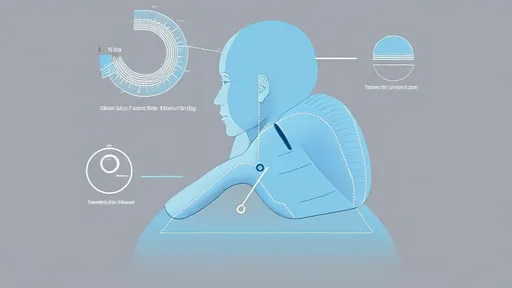

Beyond lab tests, real-world variables complicate UPF validation. For example, a jacket’s UPF might drop when stretched over shoulders or dampened by perspiration, as moisture can alter fabric porosity. Some advanced textiles incorporate hydrophilic coatings to counteract this effect, but independent verification remains essential. Third-party certifications from organizations like the Skin Cancer Foundation or the UV Standard 801 label provide additional credibility, as they audit testing processes and require stringent pass/fail criteria.

The rise of "fast fashion" UPF garments has also sparked concerns about greenwashing. Some brands exploit loopholes by testing fabrics in ideal conditions (e.g., unstretched, dry, or new) to inflate ratings. Consumers should scrutinize labels for terms like "UPF 50+" and look for specific test standards cited. Transparency reports or batch-level test results from manufacturers can further validate claims. For high-risk activities like beach sports or hiking, investing in multi-season, dermatologist-recommended apparel often proves safer than budget alternatives.

Emerging technologies are refining UPF verification. Spectral imaging, for instance, can now map UV protection across an entire garment, identifying weak spots like seams or stretched areas. Meanwhile, blockchain-based traceability systems allow consumers to access a product’s full testing history via QR codes. These innovations, coupled with global harmonization of testing standards, promise a future where UPF ratings become as trustworthy as SPF labels on sunscreen.

Ultimately, while UPF-rated clothing is a powerful tool against sun damage, its efficacy depends on rigorous, transparent testing. Consumers must educate themselves on verification methods, and brands must prioritize accountability—because when it comes to UV protection, the stakes are nothing less than long-term health.

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025

By /Jul 28, 2025